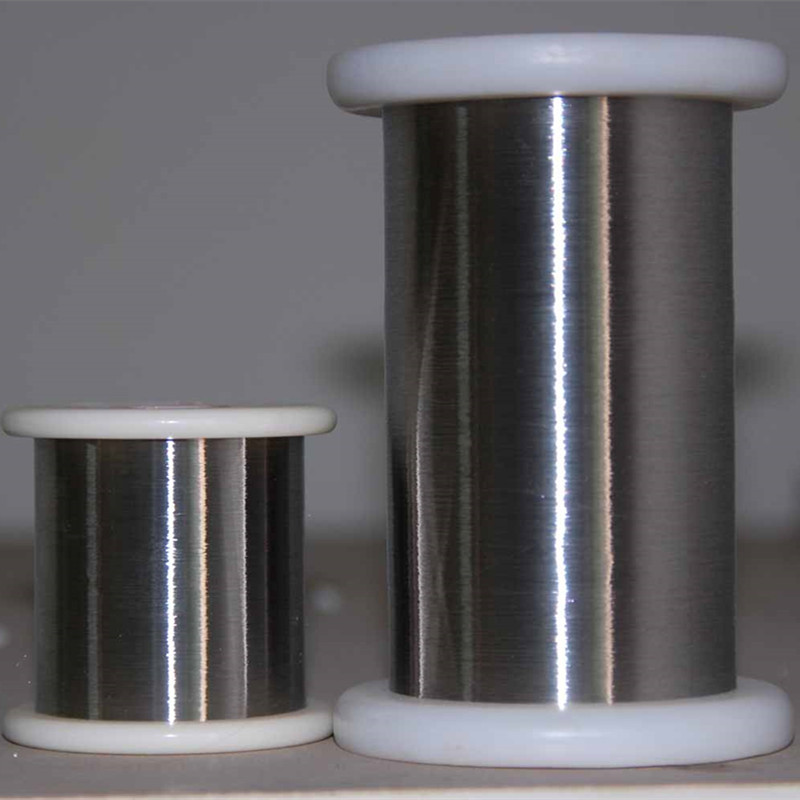

Nickel Chromium NiCr Alloy Waya

0.03mm Waya NiCr Alloy, 637 MPA Nickel Chromium Na-ekpo ọkụ Waya, Ni90Cr10 NiCr Alloy

Ni90Cr10 bụ austenitic nickel-chromium alloy kwesịrị ekwesị maka ngwa okpomọkụ ruo 1250ºC. Ọdịnaya chromium dị elu (30% na nkezi) na-enye ezigbo oge ndụ, ọkachasị na ngwa ọkụ, a na-ejikarị ya na vape, dị ka ihe na-ekpo ọkụ.

A na-eji Ni90Cr10 mara elu resistivity, ezigbo oxidation resistance, ezigbo ductility mgbe ejiri ya na ọmarịcha weldability. Alloy adịghị edobe “ire ere akwụkwọ ndụ akwụkwọ ndụ” ma dabara nke ọma maka ibelata na ikuku ikuku.

A na-eji Ni70Cr30 mee ihe maka ọkụ ọkụ eletrik na ọkụ ụlọ ọrụ. Ngwa ndị a na-ahụkarị bụ: ọkụ eletrik na ọkụ enamling, igwe nchekwa nchekwa, ọkụ na kiln nwere ikuku na-agbanwe agbanwe.

Ngwa nke NiCr Alloy Wires:

Ihe nickel-chromium nwere ike dị elu nke okpomọkụ na ike plasticity.

A na-eji ya eme ihe na ọkụ eletrik ụlọ ọrụ mmepụta ihe, ngwa ụlọ, ngwaọrụ infrared dị anya.

Nickel-chromium na ígwè, aluminum, silicon, carbon, sulfur na ihe ndị ọzọ nwere ike ime ka ọ bụrụ waya nickel-chromium alloy na nnukwu resistivity na okpomọkụ na-eguzogide. Ọ bụ ihe na-ekpo ọkụ ọkụ eletrik nke stovu eletrik, igwe igwe eletrik, igwe eletrik, wdg.

Uru nke nickel-Chromium waya:

Nguzogide dị elu dị elu, oyi akwa dị elu nwere ezigbo nguzogide oxidation, na ike mkpakọ na-anọgide na-adị mma karịa nke ígwè-chromium-aluminom waya n'okpuru ebe obibi okpomọkụ dị elu, na ọrụ okpomọkụ dị elu adịghị mfe ịmepụta nrụrụ. Nickel-chromium waya nwere ezigbo nrụrụ rọba, njirimara nhazi dị mma na ike-ike, dị mfe ịmepụta na nhazi, dị mfe ịrụzi ma sie ike ịgbanwe n'usoro. Na mgbakwunye, waya nickel-chromium nwere nnukwu ikuku, ezigbo nguzogide corrosion na ogologo oge ngwa.

Tebụl arụmọrụ nickel-chromium alloy

| Ihe eji arụ ọrụ | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

| Ihe mejupụtara | Ni | 90 | Zuo ike | Zuo ike | 55.0 ~ 61.0 | 34.0 ~ 37.0 | 30.0 ~ 34.0 |

| Cr | 10 | 20.0 ~ 23.0 | 28.0 ~ 31.0 | 15.0-18.0 | 18.0 ~ 21.0 | 18.0 ~ 21.0 | |

| Fe |

| ≤1.0 | ≤1.0 | Zuo ike | Zuo ike | Zuo ike | |

| Okpomọkụ kacha ℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Ebe mgbaze ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Njupụta g/cm3 | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Nguzogide |

| 1.09± 0.05 | 1.18± 0.05 | 1.12± 0.05 | 1.00± 0.05 | 1.04± 0.05 | |

| μΩ·m,20℃ | |||||||

| Elongation na mgbawa | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Okpomọkụ akọwapụtara |

| 0.44 | 0,461 | 0,494 | 0.5 | 0.5 | |

| J/g. ℃ | |||||||

| Thermal conductivity |

| 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| KJ/mh ℃ | |||||||

| Ọnụọgụ nke ahịrị mgbasawanye |

| 18 | 17 | 17 | 19 | 19 | |

| a × 10-6 / | |||||||

| (20~1000 ℃) | |||||||

| Ọdịdị micrographic |

| Austenite | Austenite | Austenite | Austenite | Austenite | |

| Njirimara magnetik |

| Enweghị magnetik | Enweghị magnetik | Enweghị magnetik | magnetik adịghị ike | magnetik adịghị ike | |