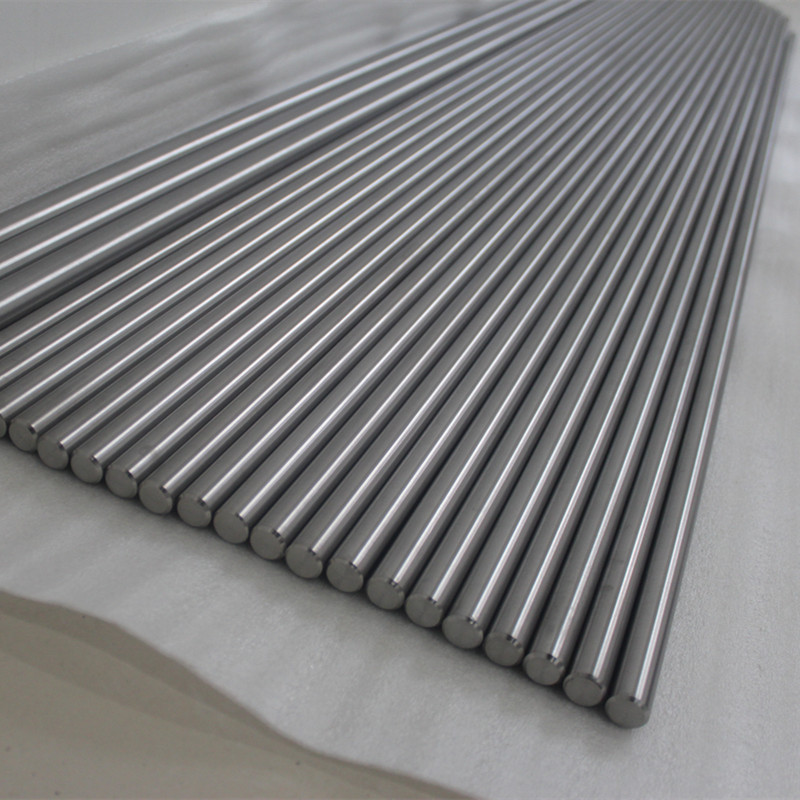

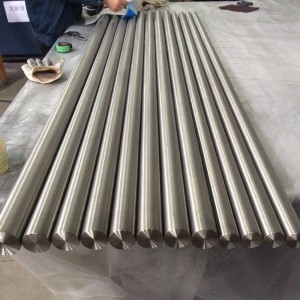

Mkpanaka Titanium Alloy Bar dị ọcha

Nkọwa

mkpanaka Titanium bụ akụrụngwa eji eme titanium alloy na titanium metal. Ọ nwere njirimara nke njupụta dị ala, ike dị elu na ezigbo nguzogide corrosion. N'ime ụlọ ọrụ ikuku, a na-eji mkpanaka titanium eme ihe n'ọtụtụ ebe na-emepụta akụkụ nhazi ụgbọ elu na rocket nozzles; na ụlọ ọrụ kemịkalụ, a na-eji ya dị ka onye na-ebu ihe na-eme ka ọ bụrụ ihe na-eme ka ọ dị ọcha maka electrolytes; na ụlọ ọrụ igwe, enwere ike iji ya dị ka ihe na-ekpo ọkụ na ihe na-ekpo ọkụ.

N'ime ụlọ ọrụ na-emepụta ihe, a na-ejikarị titanium mkpanaka / mmanya na-emepụta ígwè dị ọcha dị iche iche, igwe anaghị agba nchara, ígwè na-eguzogide okpomọkụ na ígwè pụrụ iche. Tụkwasị na nke a, a na-ejikwa ya na-emepụta nkume ndị na-emepụta ihe na rutile zircon crystals, piezoelectric ceramic sheets maka ụlọ ọrụ ngwá electronic, na nkedo ziri ezi nke ụdị dị iche iche.

Mkpanaka Titanium dị ọcha / Titanium Alloy Bar nkọwapụta

Titanium Alloy Ọkwa:Gr.5, Gr.23, Ti-6Al-4v-Eli, TI5, BT6, Ti-6al-7Nb.

Ọkwa titanium dị ọcha azụmaahịa:Gr.3, Gr.4 dị ọcha azụmahịa.

Oke dayameta:Ø5mm, Ø6mm, Ø8mm, Ø12mm, Ø14mm, Ø25mm, Ø30mm, wdg.

Ọkọlọtọ nnabata:ISO 286.

Ọkọlọtọ:ASTM F67, ASTM F136, ISO 5832.

Ogologo dị:2.5 m ~ 3 m (98.4 ~ 118.1"), ma ọ bụ ahaziri.

Izi ezi:zuru okè maka CNC machining.

All Titanium na Titanium Alloy Rods / Ogwe nwere ike ịnye ya na dayameta ma ọ bụ ogologo ahaziri ahazi, iji dabara ihe ndị ahịa chọrọ.

Njirimara nke mkpanaka alloy titanium:Mgbanwe dị mma, ike dị elu na microstructure na-arụkọ ọrụ ọnụ.

Ọkwa titanium dị

| ASTM B265 | GB/T 3620.1 | JIS H4600 | Ọdịnaya elementrị (wt%) | ||||||

| N, Max | C, Max | H, Max | Fe, Max | O, Max | Ndị ọzọ | ||||

| Dị ọchaTitanium | Gr.1 | TA1 | Klas 1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | - |

| Gr.2 | TA2 | Klas 2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | - | |

| Gr.3 | TA3 | Klas 3 | 0.05 | 0.08 | 0.015 | 0.30 | 0.35 | - | |

| Gr.4 | TA4 | Klas 4 | 0.05 | 0.08 | 0.015 | 0,50 | 0.40 | - | |

| TitaniumAlloy | Gr.5 | TC4Ti-6 Al-4V | Klas 60 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | Al:5.5-6.75;V: 3.5-4.5 |

| Gr.7 | TA9 | Klas 12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | Pd: 0.12-0.25 | |

| Gr.11 | TA9-1 | Klas 11 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | Pd: 0.12-0.25 | |

| Gr.23 | TC4 ELI | Klas 60E | 0.03 | 0.08 | 0.0125 | 0.25 | 0.13 | Al:5.5-6.5;V: 3.5-4.5 | |