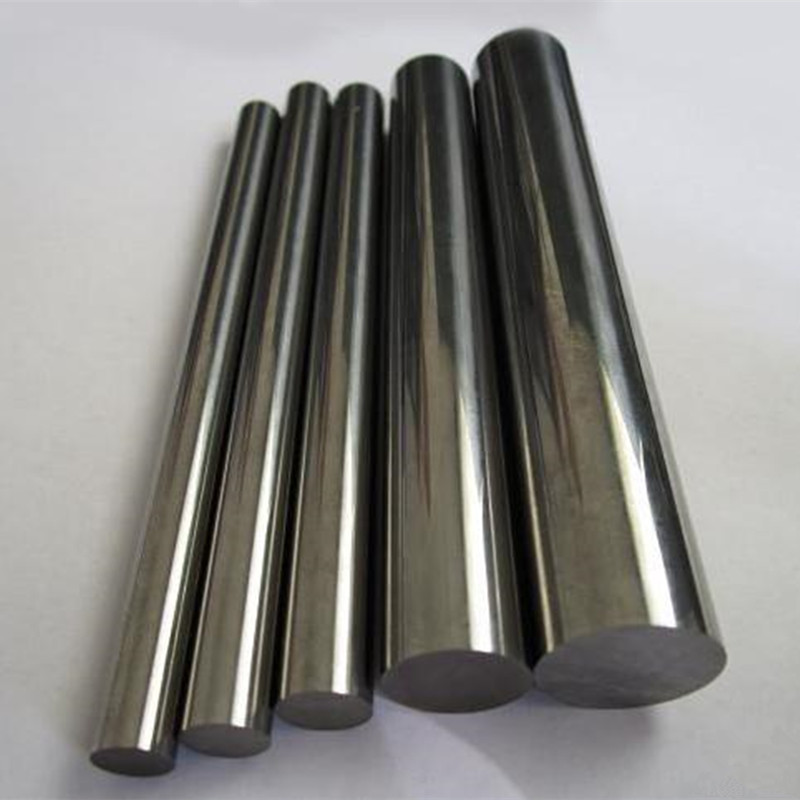

Tungsten Heavy Alloy Rod

Nkọwapụta

Ọkwa Tungsten Heavy Alloy:

W90NiFe/W92.5NiFe/W93NiFe/W95NiFe/W97NiFe (Obere Igwe Ọdụdọ).

W90NiCu/W92.5NiCu/W93NiCu/W95NiCu/W97NiCu (Na-abụghị magnetik).

Njupụta:16.8-18.8g/cm3.

Elu:Machined & Ground.

Ọkọlọtọ:ASTM B777.

Dayameta:5.0mm - 80mm.

Ogologo:50mm-350mm.

Tungsten High Njupụta Alloy Uru

Njupụta dị elu (ruo 65% denser karịa Lead).

Ihe ndị dị nchara dị (Tungsten dị ọcha, ọla edo, ọla ndị otu platinum) mana ejiri ya mee ihe bụ na ịdị adị, ịrụ ọrụ na ọnụ ahịa amachibidoro ya.

Na-enye uka ebe ohere olu dị oke.

Arọ gbadoro anya dị mkpa ebe achọrọ izi ezi na ntinye nke oke.

Ntinye nke ibu n'ọnọdụ ebe ikuku ikuku nwere mmetụta dị ukwuu.

Njirimara okpomọkụ nke Tungsten Heavy Alloys

Okpomọkụ dị nro dị elu.

Igwe ọkụ ọkụ dị ala na ọnụ ọgụgụ dị ala nke mgbasawanye na-enye ihe dị elu na-eguzogide ike ọgwụgwụ okpomọkụ.

Magburu onwe soldering ozize iguzogide aluminom gbazere.Ike na elu okpomọkụ na elu thermal kwụsie ike.

Ngwongwo ihe eji arụ ọrụ Tungsten High Njupụta Alloy

● High Young modul nke elasticity.Ọ naghị akpụ akpụ mgbe enwere ike dị egwu, n'adịghị ka Lead.

● N'agbanyeghị ike ha, ha na-anọgide ductile na-eguzogide ọgwụ mgbawa.

● Ogologo ike nke alloys bụ 20-35 Hardness HRC.

Alloy dabere na Tungsten njupụta dị elu

| Ụdị Alloy(%) | HD17 90W 6Ni 4Cu | HD17D 90W 7Ni 3Fe | HD17.5 92.5W 5.25Ni 2.25Fe | HD17.6 92.5W Balance Ni, Fe, Mo | HD17.7 93W Balance Ni, Fe, Mo | HD18 95W 3.5Ni 1.5Cu | HD18D 95W 3.5Ni 1.5Fe | HD18.5 97W 2.1Ni .9Fe |

| MIL-T-21014 | Klas 1 | Klas 1 | Klas 1 | - | - | Klas 3 | Klas 3 | Klas 4 |

| SAE-AMS-T-21014 | Klas 1 | Klas 1 | Klas 2 | - | - | Klas 3 | Klas 3 | Klas 4 |

| AMS 7725 C | 7725C | 7725C | -- | -- | -- | -- | -- | -- |

| ASTM B777-87 | Klas 1 | Klas 1 | Klas 2 | - | - | Klas 3 | Klas 3 | Klas 4 |

| Njupụta a na-ahụkarị(g/cc) | 17.1 | 17.1 | 17.5 | 17.6 | 17.7 | 18 | 18 | 18.5 |

| Njupụta a na-ahụkarị(lbs/n'ime 3) | 0,614 | 0,614 | 0,632 | 0,636 | 0,639 | 0.65 | 0.65 | 0,668 |

| Isi ike RC | 24 | 25 | 26 | 30 | 32 | 27 | 27 | 28 |

| Ike Tensile kacha elu Min(ksi) | 110,000 | 120,000 | 114,000 | 120,000 | 125,000 | 110,000 | 120,000 | 123,000 |

| 0.2% Mwepu Mbipụta Ike Min(ksi) | 80,000 | 88,000 | 84,000 | 90,000 | 95,000 | 85,000 | 90,000 | 85,000 |

| Opekempe % elongation(1 "ogologo ogologo) | 6 | 10 | 7 | 4 | 4 | 7 | 7 | 5 |

| Oke Elastic Proportional(PSI) | 45,000 | 52,000 | 46,000 | 55,000 | 60,000 | 45,000 | 44,000 | 45,000 |

| Modul nke Elasticity(x106psi) | 40 x 106 | 45 x 106 | 47 x106 | 52 x 106 | 53 x 106 | 45 x 106 | 50 x 106 | 53 x 106 |

| Ọnụọgụ nke Mgbasawanye okpomọkụ x10-6/0C(20-400C) | 5.4 | 4.61 | 4.62 | 4.5 | 4.5 | 4.43 | 4.6 | 4.5 |

| Nrụpụta okpomọkụ(Ngalaba CGS) | 0.23 | 0.18 | 0.2 | 0.27 | 0.27 | 0.33 | 0.26 | 0.3 |

| Igwe ọkụ eletrik(% IACS) | 14 | 10 | 13 | 14 | 14 | 16 | 13 | 17 |

| Magnetik | No | Dị ntakịrị | Dị ntakịrị | Dị ntakịrị | Dị ntakịrị | No | Dị ntakịrị | Dị ntakịrị |